TOPIC: TESTING OF HEARING PROTECTORS AND NEW REGULATIONS

ORIGIN: Moldex® Technical Services Department

DATE: August 17, 2009

REVIEWED: March 2010

Overview

Hearing protection is a very important part of personal safety. When exposure to excessive noise occurs, hearing loss can result. The Occupational Safety and Health Administration (OSHA) has requirements as to how much noise an employer is allowed to expose their employees to and requires that engineering or administrative controls be used to reduce these excessive exposures. OSHA realizes that it is not always possible to eliminate the excessive exposure without hearing protection devices. OSHA may require the use of these devices, but the Environmental Protection Agency (EPA) regulates how these devices are tested and labeled by the manufacturer.

The Environmental Protection Agency’s Noise Control Act, 40 CFR Part 211, governs the testing and labeling of hearing protection devices. Hearing Protection Devices include disposable earplugs, reusable earplugs, bands and earmuffs. All these products are tested in a similar fashion. Ultimately, each manufacturer of a device must have their products tested and labeled in accordance with this regulation. This rating is called a Noise Reduction Rating (NRR) and provides a number of how well a protector works under optimal conditions. The regulation that governs this rating system has not been updated in almost 3 decades.

On August 5, 2009, the EPA released a proposed revision to the standard which will change the way the hearing protectors are tested and rated. Some of the reasons for these proposed changes are that there are numerous new technologies and devices that have been developed since the regulation was written which are difficult to rate under the old system. The current testing system is based on a test protocol that has been updated several times. Finally, since there is great variability in how well each protector actually works on an individual, the EPA proposes that the rating system should reflect this variability.

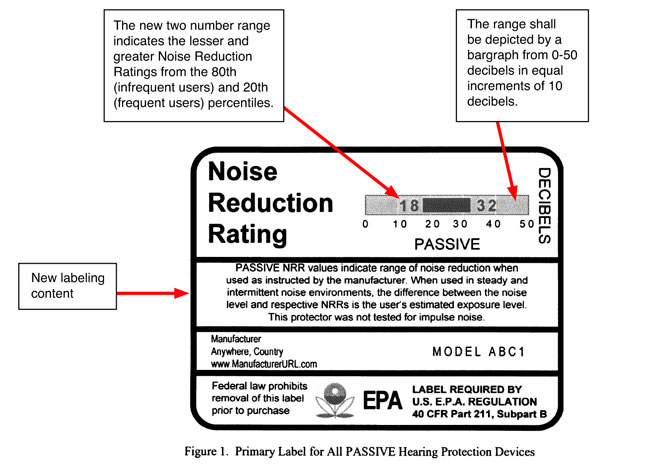

Although we do not yet know what the final required NRR rating labeling will look like, EPA has indicated that it will likely give a range of how well a protector will perform depending upon each individual’s fit; This range might indicate how well the protector will work for users with a very good fit, how well it might work for average wearers and how well it will work for those with a less than adequate fit. An example of the proposed new labeling is shown below:

For the complete report go to: https://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=STANDARDS&p_id=9737

Here is a quick overview of the most important proposed changes:

- Transition testing required for all existing HPD products using the new ANSI and EPA test methods and rating scheme.

- Labeling all existing products to incorporate the new NRR range information and new label content; applicable to both primary and secondary labels.

- Requirement for all manufacturers to complete the new testing requirements for all hearing products within thirty (30) months from the effective date of this proposed rule which will provide adequate time for depletion of existing inventories which had been tested and labeled pursuant to the 1979 regulation.

- Recurrent testing for all HPDs at either 3 or 5 year intervals.

- Changing the label to reflect a new NRR range of any product for which the recurrent testing yields NRRs that are significantly lower or higher than previously stated on the products label.

- Additional recordkeeping and reporting costs attendant to the periodic retests.

Moldex® Solution

Keep well informed and be prepared to educate end users on the new EPA regulations and rating systems. See all of our hearing products at: http://stage.moldex.com/hearing-protection/

WARNING: The information contained in this Tech Brief is dated and was accurate to the best of Moldex’s knowledge, on the date above. It is not meant to be comprehensive, nor is it intended to be used in place of the warning/use instructions that accompany Moldex respirators. Outside of the USA, check with all applicable and local government regulations.

©2003-2010 Moldex-Metric, Inc. All Rights Reserved.